made in Germany…

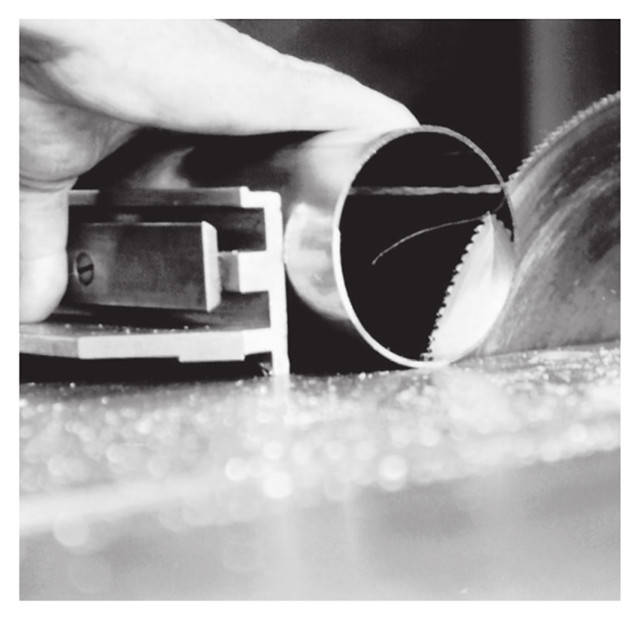

Hand-sawing with a circular saw is one of the typical methods of work employed by a brass ornament maker. No other metalworking trade takes this liberty. Similar to the cabinetmaker, the brass ornament maker thus requires a feel for the material to cut it to size.

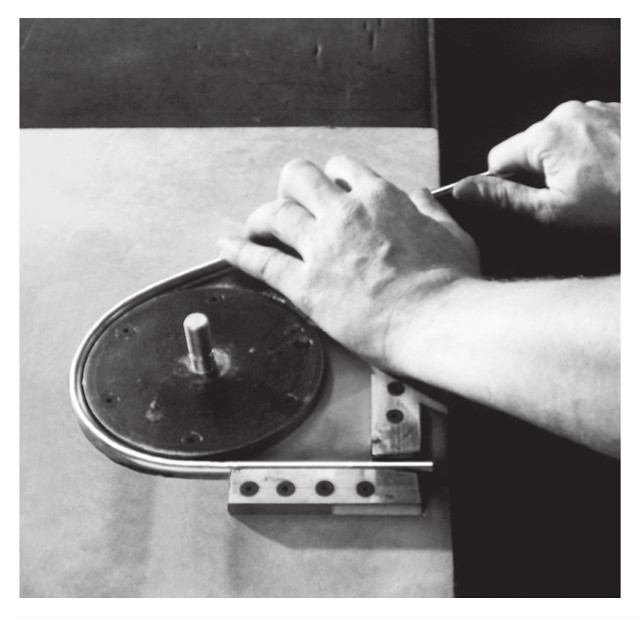

For the small production runs which we customarily handle, bending by hand is often more economical than making forms for bending machines and other motor-driven equipment.

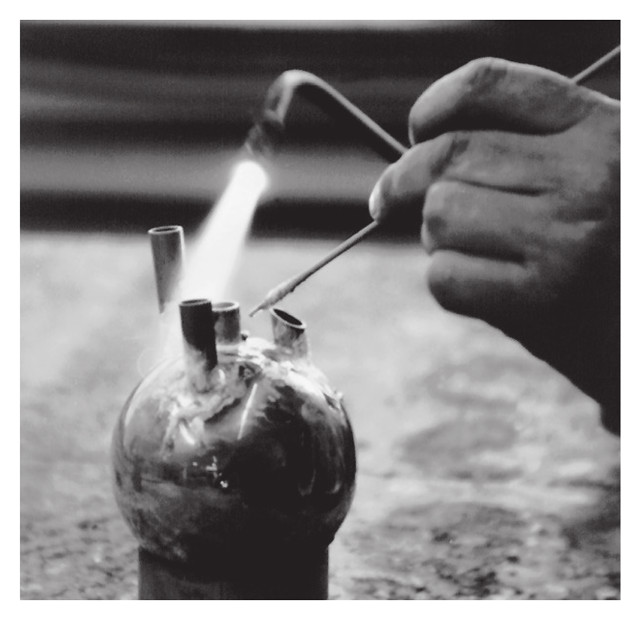

Hard soldering is the most important joining method employed by the brass ornament maker. An alloy containing up to 60 % silver is melted into the carefully prepared joint. Owing to extensive aftertreatment, the seam remains practically invisible.

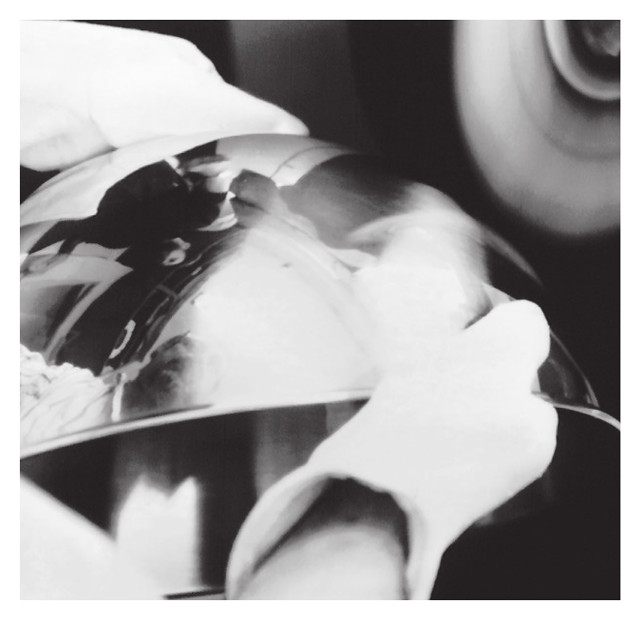

Polishing requires many years of experience. Not only is it a physically demanding job, it also requires a very sensitive approach to the workpiece.